PRODUCT

Let me introduce you to various products of DAE KYOUNG TECH.

Let me introduce you to various products of DAE KYOUNG TECH.

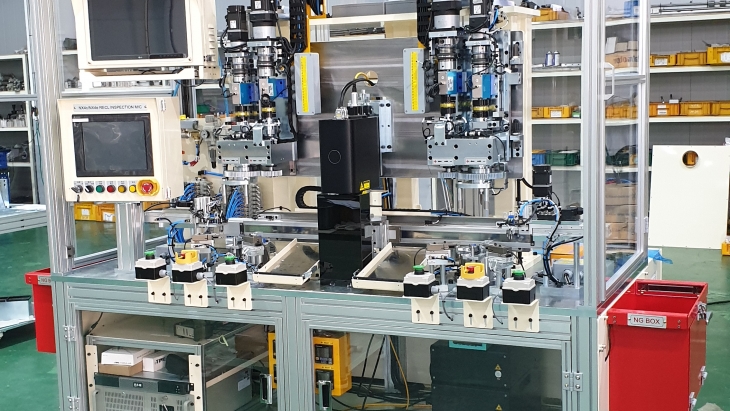

TEST EQUIPMENT OF FRT SEAT BACK ADJUSTMENTS BY LEFT AND RIGHT RECLINER WELDED PRODUCTS ARE

AUTOMATICALLY PERFORMED MAIN FUNCTION AND PERFORMANCE INSPECTIONS, COLLECT DATA IN P.C STORE

AND MANAGE THE RESULTS

COMPOSTION : FULL PROOF / LEVER OPERATION FORCE / ACTUATING FORCE / FREEPLAY TEST /

INITIAL POSITION TEST / MARKING / DISCHARGE / NG DISCHARGE

C/TIME : 17 sec / 1 ea

DATA MANAGEMENT : PLC & PC Software

SIZE : 5,500 (L) X 2,000 (W) X 2,300 (H)

※ EXPLAIN FOR EACH PROCESS

1. LOADING PRODUCT : IT IS PROCESS TO SUPPLY SEQUENTLY THE WORKER AT JIG THE PRODUCT YOU WANT TO EXAMINE

2. FOOL PROOF : IT IS PROCESS OF JUDGEMENT WHETHER OR NOT MATCH THE TARGET YOU WANT TO EXAMINE (IT CHECKS TO SUPPLY OTHER MATERIAL), OPERATING INSPECTION PIN FROM TOP TO BOTTOM IF PRODUCT SUPPLY.

IT JUDGES PASS OR FAIL SEEING TO BE TURNED ON THE SENSOR

3. TAME : IT IS PROCESS TO TAME PRODUCT FOR THE FIRST TIME APPLIED FOR ROTATION WAY OF SERVO MOTOR IN ORDER TO SOFT HANDLING AHEAD OF INSPECT OPERATING POWER

4. OPERATION POWER INSPECTION : IT IS PROCESS OF JUDGEMENT OF PASS OR FAIL TO MEASURE AUTOMATICALLY TORQUE TOOK THE BACK OF A CHAIR ROTATING SERVO MOTOR WITH TORQUE CELL

5. MANIPULATION POWER AND LOCKING ANGLE INSPECTION : IT IS PROCESS OF JUDGEMENT OF PASS OR FAIL TO MEASURE AUTOMATICALLY TORQUE WHEN RELEASE LEVER BY HAND IN ORDER TO MOVE THE BACK OF A CHAIR ROTATING SERVO MOTOR WITH TORQUE CELL

6. FREE-PLAY INSPECTION : IT IS PROCESS OF AUTOMATICALLY INSPECTION FOR CHAIR’S FREE-PLAY WHEN THE PERSON SIT DOWN ON THE CHAIR TO USE TORQUE CELL AND DIGITAL GAUGE

7. DELIVERY POSITION INSPECTION : IT IS PROCESS THE JUDGEMENT OF PASS OR FAIL SEEING TO BE TURNED ON THE RELEVANT SENSOR TO PUSH INSPECTION PIN ABOUT CORRESPOND THE PLACE WHEN INTIAL INPUT AFTER COMPLETE FINAL INSPECTION

8. MARKING : IT IS PROCESS TO TAKE THE UNIQUE NUMBER OF PRODUCT TO USE DOT MARKING MACHINE ON INSPECTION FINISHED PRODUCT (IT IS SAME TO GET THE I.D NUMBER)

9. OUTPUT FINISHED PRODUCT : IT IS PROCESS OF EMISSION AUTOMATICALLY TO WORKER BY CONVEYOR ABOUT FINAL PRODUCT THAT MARKING IS COMPLETED

10. NO GOOD PRODUCT OUTPUT : IT IS PROCESS OF AUTOMATICALLY SEPARATION EMISSION TO THE EQUIPMENT REAR FOR THE PRODUCT THAT PROVES THE FAIL IN THE EXAMINATION PROCESS

(IT CONSIST OF SEPARATION CONVEYOR TO BAN PUTTING TOGETHER GOOD PRODUCT)

이메일 무단수집을 거부합니다.

본 웹사이트에 게시된 이메일 주소가 전자우편 수집 프로그램이나 그 밖의 기술적 장치를 이용하여 무단으로 수집되는 것을 거부하며, 이를 위반시 정보통신망법에 의해 형사 처벌됨을 유념하시기 바랍니다.